There’s More to a Teabag Than Meets the Eye

When it comes to the simple act of drinking a cup of tea, there’s a lot more to consider than just choosing the right tea. The material of the teabag and its bonding process are equally crucial. These factors not only determine the durability of the bag, but also directly impact the safety and quality of every sip you take.

Improper bonding leads to “plastic-flavored” tea.

Some teabag materials require high temperatures for bonding, which can negatively affect the packaging. Adhesive-based bonding may release microplastics or other harmful substances during hot water brewing, compromising user safety. Additionally, bags with insufficient bonding strength may break during brewing or transport, causing tea to spill out and affecting the overall experience.

Polylactic Acid (PLA) Fiber: Secure Sealing, Safe Brewing

Also known as “corn fiber,” PLA fiber has gained popularity in the context of sustainable consumption. Teabag materials made from PLA nonwoven fabric are becoming a new choice for both the market and consumers, thanks to their outstanding performance. So, what bonding advantages does PLA nonwoven fabric offer?

1. Ultrasonic and Thermal Bonding Capabilities to Boost Production Efficiency

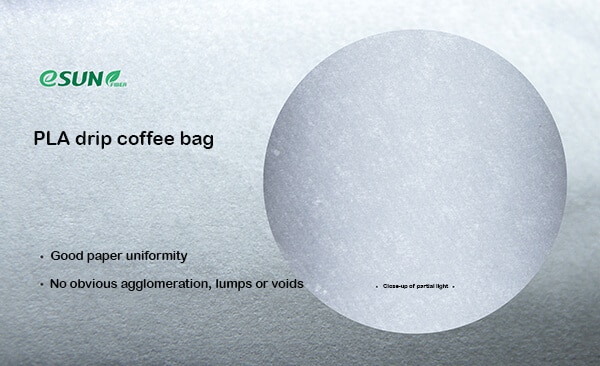

eSUN’s PLA fibers can be used in wet-laid and dry-laid processes for specialty paper production. Applications include teabags, coffee pods, coffee filters, herbal sachets, spice pouches, foot bath bags, dust-free paper, and other packaging materials. Using PLA fiber in pulp and paper processes allows for ultrasonic thermal bonding, reducing costs and improving production efficiency.

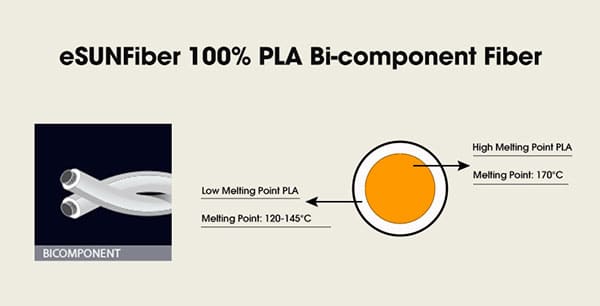

In addition, eSUN’s PLA bicomponent fiber features a core-sheath composite structure made of 100% polylactic acid. The sheath is a low-melting-point PLA with good softness, while the core is a high-melting-point PLA with high strength.

This PLA bicomponent fiber can replace traditional bonding fibers such as PP and PET ES fibers, enabling ultrasonic or thermal bonding without the need for additional adhesives—achieving natural, safe, and fully biodegradable products.

2. Adjustable Bonding Temperatures to Suit Different Equipment Requirements

PLA fibers can be engineered to achieve different bonding temperature combinations, meeting the technical needs of various teabag packaging machines.

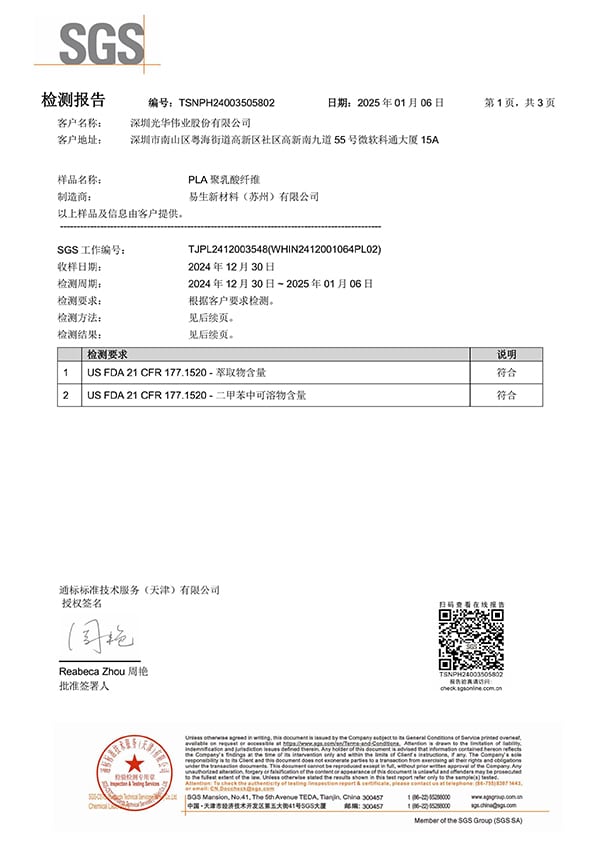

3. Safe and Eco-Friendly – No Harmful Substance Release

Derived from bio-based materials, PLA fibers do not release toxic gases or unpleasant odors during thermal bonding. In applications such as teabags, PLA ensures a clean brew free from off-flavors or harmful substances. This makes it suitable for food, hygiene, and medical packaging where safety and odor control are critical.

4. Neat Bonding Edges and Excellent Appearance

Thanks to the moderate flowability of molten PLA, it does not cause excessive shrinkage or adhesive overflow during bonding. This results in clean, flat edges without significant wrinkles or scorching. For products requiring a tidy appearance—such as cosmetic packaging or medical protective bags—PLA nonwoven fabrics enhance overall product quality.

5. Maintains Biodegradability After Bonding

PLA fibers can be bonded through ultrasonic or thermal processes without introducing third-party materials, preserving the full biodegradability of the final product. This supports global trends of plastic reduction and environmental protection, achieving a “no-trace tea experience.”

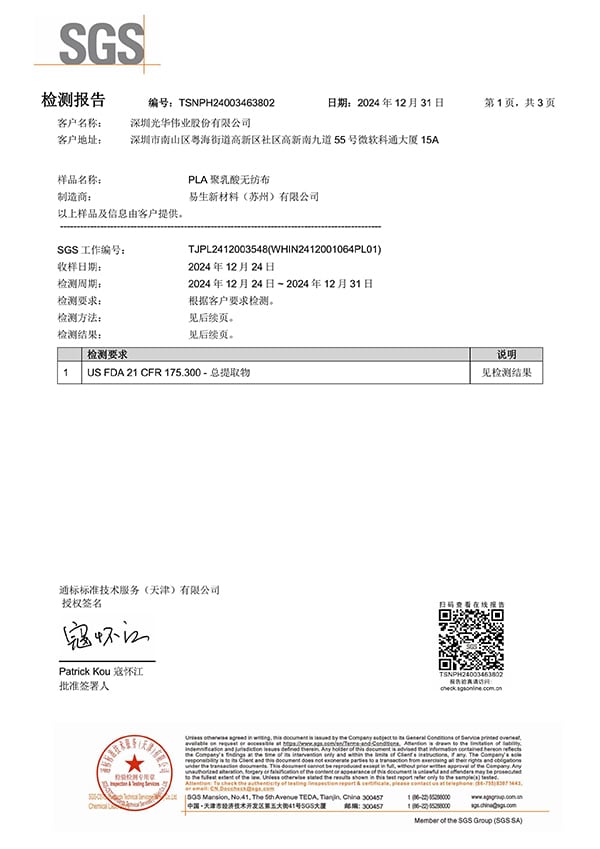

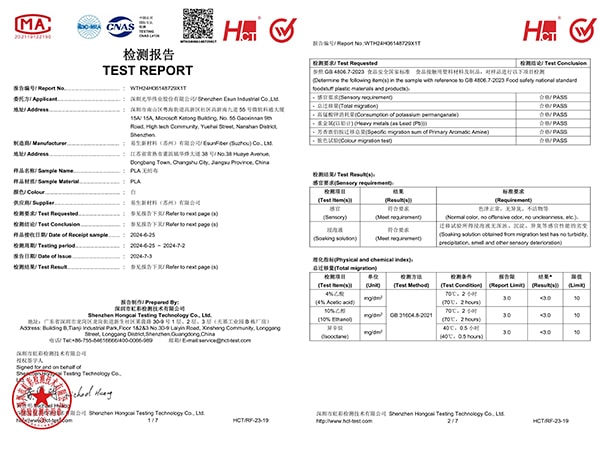

PLA fibers are derived from renewable plant-based resources and exhibit excellent biocompatibility. They are widely used in food, pharmaceutical, and high-standard household paper applications. eSUN’s PLA fibers and nonwoven fabrics have passed domestic and international food safety certifications.

For more information, feel free to contact us!