Viscose fiber, also known as rayon, is a regenerated cellulose fiber made from natural sources such as cotton linters and wood pulp through chemical processing and wet spinning. Viscose fiber has excellent moisture absorption, breathability, and dyeing properties, and is widely used in textiles, apparel, and home furnishings.

In recent years, China’s viscose fiber industry has seen continuous development and steady growth in output. In 2023, China’s viscose fiber production reached 4.168 million tons, an increase of 8.18% year-on-year.

1. Application Advantages of PLA Fiber and Viscose Fiber

PLA (polylactic acid) fiber can be blended with cotton, linen, silk, wool, or other bio-based fibers. This not only compensates for the limitations of single-material applications but also adds multifunctionality to downstream products.

(1) Moisture Absorption, Breathability + Quick Drying

Viscose fiber is highly absorbent and breathable; PLA fiber is lightweight with excellent moisture diffusion. Their combination enhances user comfort. In applications like diapers, sanitary napkins, and disposable Sanitary products, this property helps reduce bacterial growth and improves dryness and comfort.

(2) Enhanced Antibacterial Properties and Product Functionality

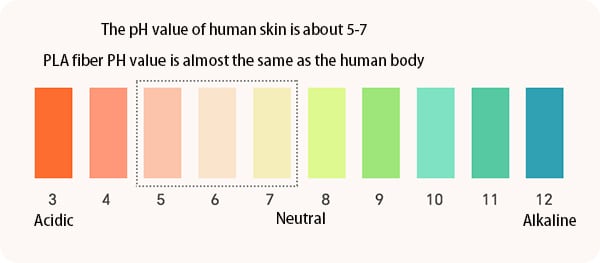

PLA is a bio-based material derived from renewable plant sources, making it naturally safe. Its slightly acidic surface (from lactic acid) supports the skin’s microbial balance and offers natural antibacterial protection.

Blending PLA with viscose enhances the product’s antibacterial performance, making it ideal for skin-contact applications.

*eSUN antibacterial test report for nonwoven fabric sample (composition: 30% PLA fiber + 70% viscose fiber)

As shown above, the antibacterial test results from eSUN’s samples indicate that PLA fiber demonstrates good resistance against Staphylococcus aureus, Escherichia coli, and Candida albicans.

(3) Skin-Friendly and Soft — Promoting Use in the Apparel Industry

PLA fiber is known for its skin-care, antibacterial, odor-reducing, and moisture-wicking functions. In apparel, blending PLA and viscose enhances softness and comfort while retaining multifunctionality, catering to users’ diverse needs.

(4) Biodegradability — Reducing Environmental Pressure

Both viscose and PLA fibers are made from renewable raw materials. In disposable sanitary products, they offer excellent biodegradability and can break down into CO₂ and water under composting or natural conditions, posing no burden to the environment.

2. Application Examples of PLA Fiber and Viscose Fibers

(1) Sanitary Series — Antibacterial Spunlaced Nonwoven Fabric

Blending PLA and viscose fibers reduces costs while maintaining antibacterial, anti-mite, and deodorizing properties.

(2) Packaging Series — Heat-Sealable Spunlaced Nonwoven Fabric

Thanks to PLA’s thermal bonding properties, it can replace conventional hot-melt fibers in nonwoven manufacturing, enabling glue-free bonding and improved eco-friendliness.

(3) Apparel Applications — Blended Yarns and Fabrics

PLA and viscose blended fabrics offer diverse functionalities, suitable for all seasons. PLA’s quick-drying properties help garments recover from moisture quickly. In winter, PLA provides better insulation than cotton or polyester; in summer, its breathability and moisture diffusion enhance sweat evaporation and heat dissipation, making it ideal for next-to-skin wear.

Under the themes of “plastic reduction, carbon reduction, and environmental protection,” demand for regenerated cellulose fibers (like viscose, Tencel, Modal) is rising. Promoting the combined application of eco-friendly materials supports healthy industry development and meets users’ diversified needs.

eSUN focuses on PLA fiber nonwoven fabric and is committed to becoming a leading enterprise in differentiated and functional PLA fibers. The company has made breakthroughs in key PLA fiber production and application technologies and welcomes inquiries and collaboration to promote green, sustainable growth in the textile industry.