BIOBASED RENEWABLE

SORONA®

An advanced polymer brand developed by DuPont, USA.

As a biobased synthetic fiber, it is partially derived from renewable plant materials, reducing reliance on petroleum and carbon dioxide emissions, aligning with sustainable development trends.sorona®Core raw materials consist of 37% PDO (1,3-Propanediol) derived from corn sugar fermentation and 63% TPA (Terephthalic Acid) from petroleum refining.The second-generation Sorona® XS can increase the biobased content to 73%.

SORONA® fibers can be blended with natural or synthetic fibers, endowing related products with better elasticity and shape retention, good moisture-wicking properties, comfortable stretch recovery, etc.

What surprises await when polylactic acid fiber joins hands with Sorona fiber?

01 Increased Biobased Content, Low Carbon & Eco-friendly

SORONA® biobased material’s core raw materials come from plants, boasting high biobased content with 37% from corn-based monomers. Compared to Nylon 6, it has the following characteristics:

- 37% reduction in petroleum resource consumption

- 44% reduction in energy consumption

- 59% reduction in greenhouse gas emissions

Polylactic acid (PLA) fiber is derived from renewable plant materials.

PLA + SORONA® will further increase the biobased content of end products, reducing petroleum resource consumption and carbon dioxide emissions.

*According to the Plastics EUROPE report, the Global Warming Potential (GWP) of PLA is approximately 0.5 kg CO₂ eq/kg. Compared to typical fossil-based polymers (such as PS, PET, PP, and PE), the carbon footprint is reduced by about 75%.

Carbon Dioxide Emissions of Common Plastic Products

Unit: kg CO₂ equivalent per kg plastic product – cradle-to-gate

PC: 5.0

PS: 2.2

PET: 2.0

PP: 1.7

LOPE: 1.7

PLA: 0.5

*Source: PlasticsEurope Ecoprofiles (2023); LCA of PLA, Journal of Polymers and the Environment, (2019) and internal sources.

02 Excellent Resilience, Lasting Fluffiness

The macromolecular structure of PLA fiber determines its good resilience. At 5% tensile deformation, the elastic recovery rate of polylactic acid fiber reaches 93%.

The semi-crystalline structure of SORONA® fiber makes the molecular chains act like micro-springs, with an elastic recovery rate as high as 92%. It can automatically and quickly recover its original shape after stretching, offering good shape retention.

The combined application of the two will bring a more three-dimensional fluffy hand feel, lasting resilience performance, and stable shape retention capability.

03 Antibacterial & Anti-mite, Skin-friendly & Soft

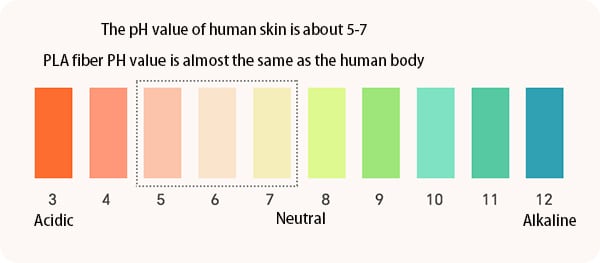

Polylactic acid fiber is naturally weakly acidic, possesses good biocompatibility, has excellent affinity with skin, and is non-allergenic.Sorona fiber has high biobased content and natural material properties. This makes the PLA × SORONA® combination even more suitable for applications close to the human body.

04 Lightweight, Safe, Tough: Hidden Performance Bonuses

Additionally, this combination comes with several “skill points”:

Lightweight and Dry: Polylactic acid fiber is lightweight and wicks moisture quickly after absorption, keeping the filling dry for a long time. Sorona fiber also possesses excellent moisture-wicking and quick-drying properties.

Self-extinguishing upon removal from fire: Polylactic acid fiber has self-extinguishing properties, produces little smoke, and is non-toxic, adding to safety assurance.

Wear-resistant and Durable: Sorona fiber endows the material with excellent abrasion resistance and durability, helping to extend the product’s service life.

Based on the above characteristics,PLA+SORONA® can be widely used in various filling scenarios

Home Textile Filling

For example, pillow cores, quilt cores, dolls, plush toy filling, cushions, and bolster filling.

Apparel Filling

For example, down jacket filling, cotton coat interlayers, thermal underwear lining.

While being lightweight and warm, it endows clothing with better breathability and elastic support.

Textiles & Intimates

Such as loungewear, casual fabrics, lining fabrics.

Balancing elasticity, softness, and shape stability.

Close to the skin, and close to the concept of sustainable living.

Daily Consumer Goods

Soft filling structures, cushioning protection materials, toy interiors, etc.

Safe, eco-friendly, flexible.

Suitable for more consumer scenarios that value experience and responsibility.

Car Headrest Filling Application

High resilience for neck support without collapsing, skin-friendly and breathable without causing sweat.

High biobased content, low carbon, and eco-friendly.

eSUN PLA Fiber

About eSUN Polylactic Acid Fiber

eSUN is dedicated to the polylactic acid fiber and non-woven fabric business.

It can provide polylactic acid staple fibers, filaments, non-woven fabrics, and yarn products.

Especially differentiated polylactic acid fibers, such as bicomponent fibers, three-dimensional fibers, etc.

It can customize fiber and non-woven products according to customer needs.

Denier: 1.5-5D Length: 38/51/64mm

PLA+SORONA® Bio-Ball

Total plant and plant-based content exceeds 50%