Wool and cashmere, as natural fibers that are skin-friendly and thermally insulating, are widely used in the apparel industry. Not only do they offer excellent warmth, but they also provide good breathability, a soft and comfortable texture, and are lightweight—making them highly favored by consumers.

In practical use, wool products require careful maintenance and have certain drawbacks. For example, untreated wool products are prone to deformation and pilling, and improper handling or storage may cause the product to yellow.

Polylactic acid (PLA) fiber, an emerging bio-based synthetic fiber, has unique functionalities and advantages. So, what new experiences can it offer when blended with wool or cashmere?

I. Advantages of Blending PLA Fiber with Wool

1.Enhanced Antibacterial Properties for an Optimized Balance Between Comfort and Functionality

PLA fiber is skin-friendly and breathable, with excellent antibacterial and anti-mite properties. When blended with wool, cashmere, and other materials, the resulting fabric combines the softness and warmth of wool with the lightness and quick-drying features of PLA fiber. It is not only environmentally friendly and comfortable, but also antibacterial, anti-mite, and hypoallergenic, making it particularly suitable for next-to-skin apparel such as wool sweaters and knitwear.

2. Improved Structure and Appearance

Blending PLA fiber with cotton, linen, silk, wool, and other materials enhances the structure and crispness of garments. This advantage becomes especially apparent in suiting fabrics or outerwear with structured silhouettes.

3. Cost Reduction for Wool-Based Products

Blending allows for maintaining fabric performance while reducing dependence on high-cost wool, thus helping to control overall production costs.

II. Applications of PLA Fiber and wool blended Fabrics

1. Apparel Applications

Knitwear, sweaters, functional underwear, base layers, etc.—the combination of wool’s lightweight warmth and PLA’s smooth, skin-friendly qualities makes it ideal for intimate apparel. Additionally, the antibacterial and anti-mite properties of PLA fiber further meet the diverse needs of users.

As shown in the image above, a wool sweater jointly developed by eSUN and its partners, made from a blend of 65% wool and 35% PLA fiber, has successfully addressed challenges related to PLA dyeing, finishing, and yarn evenness. The final product is lightweight, soft, warm, and offers antibacterial and anti-mite properties, resulting in a positive user experience.

For suiting and overcoat fabrics, the blend helps improve pilling resistance and durability while reducing garment weight and enhancing drape.

2. Home Textile Applications

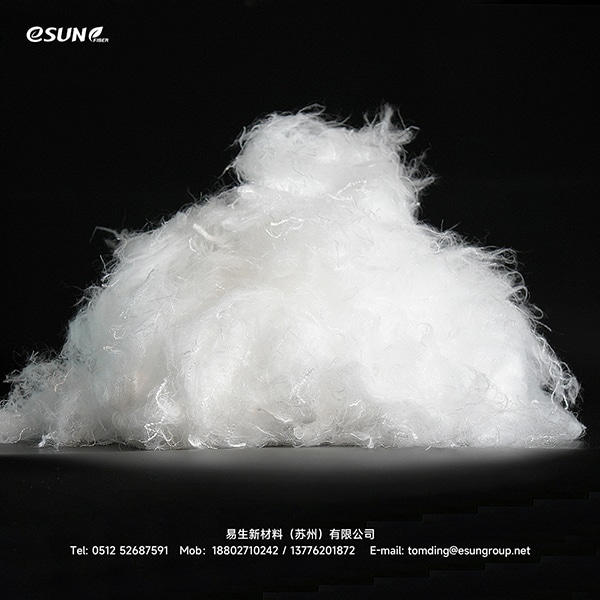

Blankets and quilt fillings—lightweight, warm, and environmentally friendly. PLA fiber can help alleviate issues such as shrinkage and deformation often seen in wool.

Carpet and cushion fabrics—durable and soft to the touch, suitable for high-end eco-friendly home textile products.

In addition, PLA fiber blended with wool can be applied in other related fields through processes such as needle punching and hydroentangling.

As the concept of sustainable development becomes increasingly embedded in public consciousness, the textile industry is actively pursuing the integration of environmental responsibility and functionality. The blending of polylactic acid (PLA) fiber with wool represents an innovative practice within this trend, playing a highly positive role in promoting the functionalization, decarbonization, fashionability, and diversification of wool textile products.

eSUN is primarily engaged in the PLA fiber nonwoven fabric business and is committed to becoming a leading enterprise in differentiated and functional PLA fibers. To date, the company has achieved breakthroughs in key technologies related to the production and application of PLA fibers. We welcome your inquiries and look forward to working together to promote the green and healthy development of the textile industry.